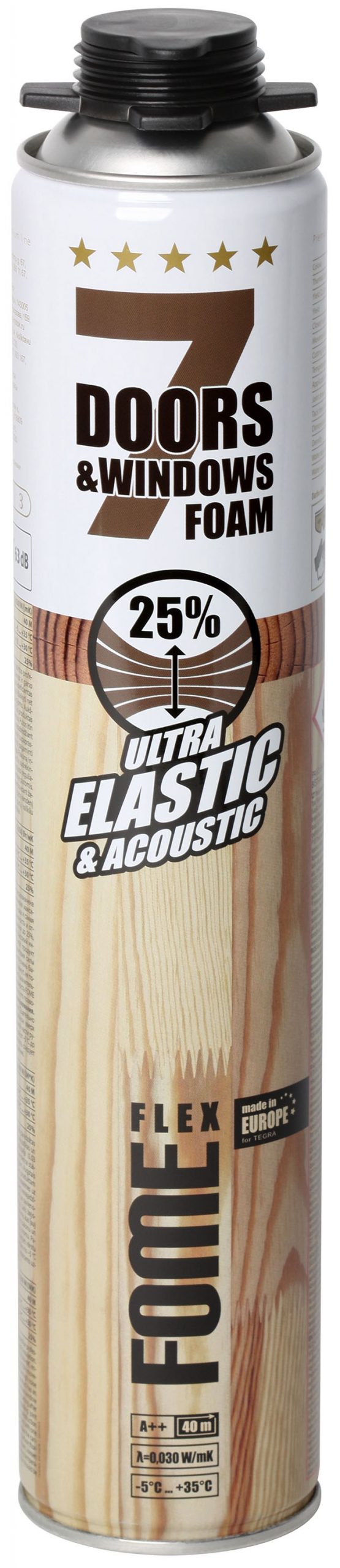

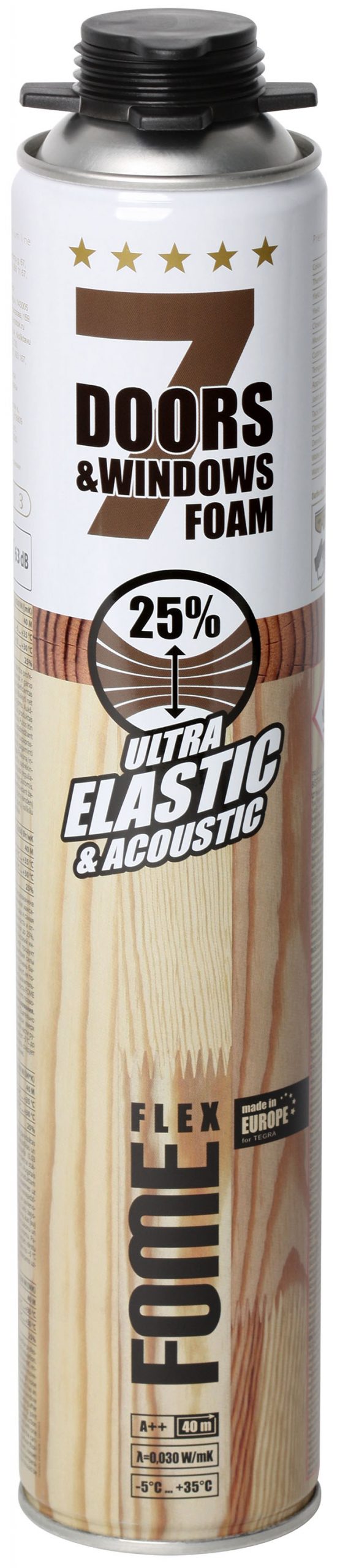

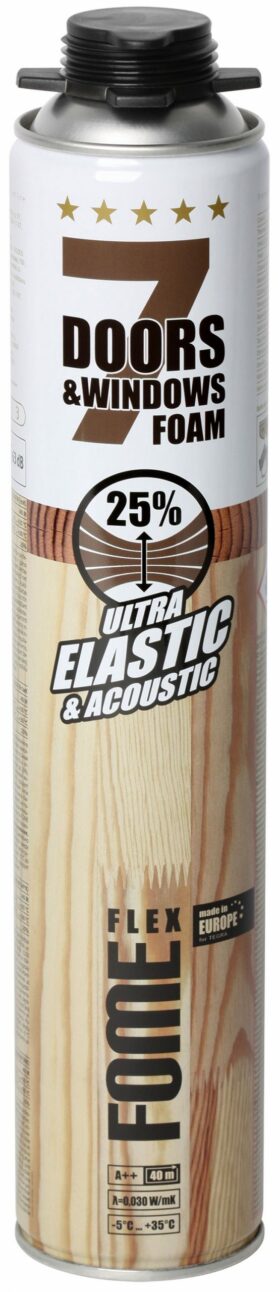

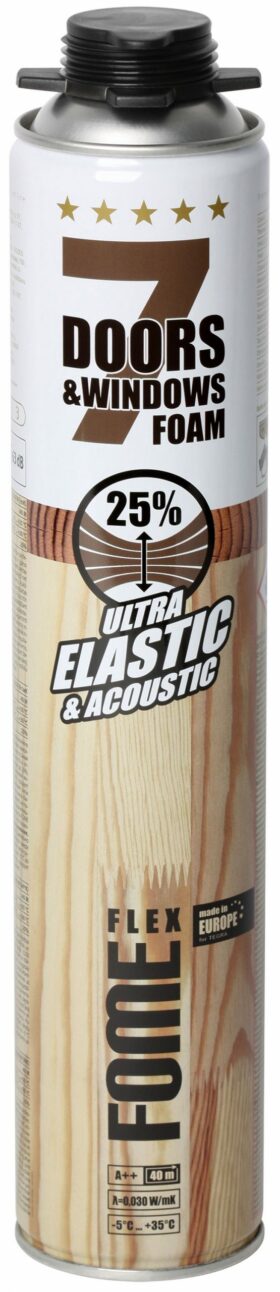

One-component polyurethane mounting foam FOME FLEX 7 DOORS WINDOWS ELASTIC PISTOL FOAM is designed for professional sealing of windows and doors, ensuring the highest thermal and sound insulation. Constant foam flexibility and the lowest thermal conductivity (0.030 W / mK) ensures durability and excellent thermal insulation. The seam can withstand up to 25% displacement, making the product ideal for moving structures. The high noise reduction index allows you to reduce the sound to 63 dB. FOME FLEX 7 DOORS WINDOWS ELASTIC PISTOL FOAM has an extremely low secondary expansion of 30% and minimal force on the window and door frames. The foam polymerizes extremely quickly, so it is possible to cut after 25 minutes, without damaging the foam structure and without deteriorating the properties of the seam. The yield of one vial is 40 meters (2.5 cm * 5 cm seam) or 40 liters by free-blowing. Fully hardens in 80-100 minutes. This significantly speeds up and simplifies the work of the master. Temperature resistance after hardening -40 °C .. + 90 °C. The foam has 70% closed and 30% open pores.