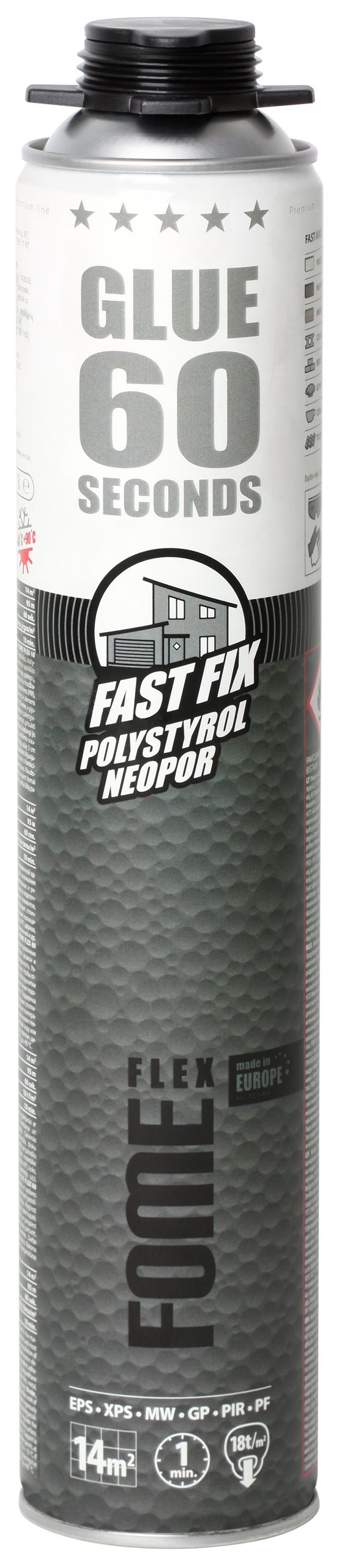

FOME FLEX 60 SECONDS FAST FIX is a premium foam adhesive engineered for speed and strength. With the fastest primary adhesion on the market and extremely low secondary expansion, it’s the go-to solution for professionals in construction, insulation installation, finishing, and general repair work.

Key Applications for FOME FLEX 60 SECONDS FAST FIX:

- Fast and secure installation of insulation boards and finishing panels, regardless of size

- Durable bonding of masonry blocks and decorative architectural elements

- Precise adhesion for steps, skirting boards, window sills, and more

Standout Features:

- Ultra-fast adhesion: Bonds in just 60 seconds, reducing downtime

- Minimal holding time: Only 1–2 minutes, depending on weight and surface

- Rapid curing: Fully cures in 15 minutes; cuttable in 10 minutes

- Exceptional compatibility: Bonds to a wide range of materials, including:

- Polystyrene boards (EPS, XPS, NEOPOR)

- Polyurethane foam (PIR), phenolic foam (PF)

- Wood, concrete, masonry, ceramic and stone tiles

- Metal, gypsum, OSB, aluminum, and more

- High yield and efficiency: One canister covers up to 95 linear meters (or approx. 14 m²) with a 3 cm seam

- Superior strength: Tensile strength of 18 kg/cm² ensures long-lasting bonds

- Eco-friendly and safe: Certified with EMICODE EC1 Plus for low emissions and human health safety

Why Choose FOME FLEX 60 SECONDS FAST FIX?

Whether you’re working on residential, commercial, or industrial projects, this fast-curing foam adhesive saves time, reduces material waste, and delivers professional-grade results. Ideal for anyone seeking high-strength, quick-adhesion construction adhesives that meet top environmental and safety standards.